You have likely heard of the OBD port if you own a vehicle. When the check engine light turns on, you may attach diagnostic equipment to your automobile using this connection to determine what is wrong. But what if the OBD port does not function properly?

Causes of an unresponsive OBD port include a blown OBD fuse, a broken OBD port, a lack of electricity at the port, an unresponsive ECU, or a damaged wire harness. Alternatively, after connecting the OBD scanner, you could not have turned the ignition to the “On” position.

You have not set the ignition to the “on” position.

It may sound absurd, but failing to switch the ignition to the “run” position is one of the most frequent causes of the OBD port “not functioning.” The ignition must be in the run position for the OBD port to turn on. The OBD port will not have electricity and will not be able to interact with diagnostic equipment if the vehicle is not started.

The OBD protocol used by the car is not standardized.

It is conceivable that your older car employs an OBD protocol that is not standardized. This implies that most diagnostic instruments available on the market cannot connect with the automobile.

Certain earlier vehicles employed proprietary protocols, such as MOBD, OBD I, ALDL, or MUTT, incompatible with the common OBD-II protocol. So, to decipher the codes, you will need a specialist diagnostic device created for that particular vehicle make and model.

A Blown OBD Fuse

The fuse powering the OBD port may have blown if it is not getting power. Under the car’s hood, in the main fuse box, is where the OBD fuse is often found. Check whether the OBD fuse has blown once you have found the box. If it has, swap it out for a new one to see whether the issue is resolved.

Damage to the OBD port

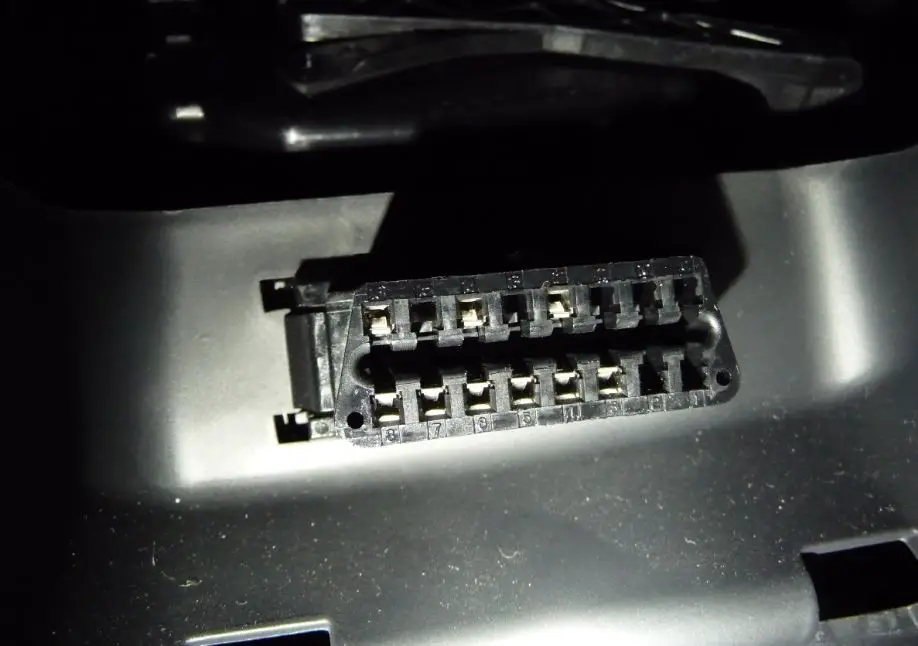

The OBD port itself has to be replaced if it is broken. The type and model of your automobile will affect how easy or difficult this procedure is for you. The OBD port’s pins themselves are the component that is most susceptible to sustaining damage. The pins may become fractured, rusted, or bent, making it difficult to connect properly with the diagnostic device.

How to Fix

Step-by-Step Instructions

If the OBD port is broken, replacing it is your best option.

- The negative battery cable disconnected. Doing this may prevent unintentional electrical shorts when working on the OBD port.

- On the driver’s side, look beneath the dashboard for the OBD port.

- The panel that covers the OBD port should be unscrewed and left aside.

- Pull the OBD port out of its casing after unplugging it from the electrical harness.

- Connect the new port to its wire harness after inserting it into its housing.

- Reinstall the panel using screws.

- The negative battery cable is reattached.

The Connections Do not Have Enough Voltage.

Another possibility is that the OBD port is not providing the diagnostic equipment with adequate power. This could occur if the battery is running low or the charging mechanism is malfunctioning. Pin 16 needs 12-v electricity to function correctly in the OBD port, while pins 4 and 5 require the ground for the scan tools to operate. Moreover, the ignition key must be in the run position.

Connect the voltmeter to the OBD port and check to see if it displays 12 volts to verify this. The battery or charging mechanism is probably the issue if it doesn’t. If changing the battery does not help, you must take it to a repair so they can examine the electrical system.

The ECU Is not Effectively Communicating.

The ECU is the computer that oversees your car’s engine management operations. If it is not functioning correctly, it may lead to various issues, including prohibiting communication between the OBD port and the diagnostic equipment.

There are many approaches to determine if the ECU is the issue. You must utilize a multimeter since you cannot interact with the ECU using a diagnostics tool.

Find the ECU. The driver’s side normally has it beneath the dashboard.

After you have located it, check to see if the ECU is securely linked to the required electrical components. The ECU will not operate correctly if any of the connections are loose.

The ECU’s power supply is the next thing to verify whether all connections are secure. Verify that the battery is supplying the ECU with adequate voltage. If it isn’t, the battery or charging mechanism is probably where the issue lies.

Use the multimeter to test each component (such as the fuse & relay) to ensure it operates correctly if the connections are tight. It will be necessary to replace the ECU if none are.

The optimal measurement for a working component should be between 1 and 1.2 amps.

A Damaged Wiring Harness

The vehicle’s wiring harness, which distributes power and data to all of the many electrical components within, is linked to the OBD port. It may be impossible for the OBD port to communicate with the diagnostic instrument if the wire harness is broken.

A multimeter is the most effective tool in addition to a visual assessment to determine whether or not the wire harness is damaged. The wire harness is most often damaged by water, so carefully look for any corrosion indications.

Find the OBD port, then unplug it from the wiring harness.

Check the wires’ continuity with a multimeter. Lack of continuity indicates a broken wire that has to be replaced.

You may also use a voltmeter if you do not have a multimeter. Connect the voltmeter to the OBD port and check to see whether it displays 12 volts to do. If it doesn’t, there is likely a wire break, which has to be addressed.

It is advisable to leave replacing the wire harness to a professional since it might be challenging to do on your own.

How Does a Port OBD II Work?

Mechanics and technicians may attach diagnostic instruments to a car’s computer using OBD II ports and vehicle diagnostic interfaces. The information delivered over the port may be used to locate mechanical, emissions, and transmission problems. The car may then be repaired or adjusted using this data.

The precise position of OBD II ports might vary depending on the make & model of the car. However, they are commonly found below the steering wheel. Often, a Phillips head screwdriver is needed to remove the protective cover. A female 16-pin connection should be visible after the lid has been removed.

A diagnostic tool has to have a male 16-pin connection to connect to the OBD II port. This kind of connection is found on many diagnostic instruments that are sold commercially. The diagnostic tool may be used to access information kept in the car’s computer system after it is attached to the OBD II port.

The control module, the data link connection, and the sensors are only a few parts of the OBD II system. The primary computer in the car that keeps track of performance data is called the control module. The control module or the diagnostic tool is physically connected through the data link connector. The sensors are used to gather information on the vehicle’s engine, gearbox, and emissions.

If you do not have an OBD II scanner tool, you may ask whether you can still read error codes. The solution is right here.

OBD I

The OBD system (OBD I), released in 1988, came before the OBD II. OBD I was created to aid in providing fundamental onboard diagnostics in cars. It was not as efficient as the 1997-introduced OBD II system, however. The OBD II system is far more thorough and has many mechanical and electrical problems it can detect.

The OBD II system is standardized, the primary distinction between the OBD I and OBD II systems. This implies that an OBD II port that complies with specified criteria must be installed in every car made after 1997. As a result, technicians and maintenance can identify issues with all automobiles using the same diagnostic instruments.

How Should I use an OBD II Tool?

OBD II scanners are used to connect to a car’s computer system and gather information on the car’s performance. You must have a male 16-pin connection appropriate for the OBD II port on your car to utilize an OBD II scanning tool. A 16-pin connection is already included with the majority of OBD II scanners. Switch the ignition after plugging the connection into the OBD II port.

The OBD II scanning equipment will be able to retrieve information from the vehicle’s computer system as soon as the ignition is switched on. The OBD II scanner will now search for the system-stored codes. The OBD II scanner tool will next need some maneuvering on your part to determine whether error codes are present.

Not all OBD II scanning tools are made equal; it is important to remember this. Certain OBD II scanner devices have an integrated display showing the codes. You will need to connect the OBD II scanning equipment to a computer to display the codes for some. After you receive the codes, you may use them to identify the issue and carry out the required fixes.

After you are done, disconnect the OBD II scanner tool from the port, then switch off the ignition.

If you are interested, we have a piece explaining more about OBD II codes.

Conclusion

An essential component of a car’s computer system is the OBD II system. It is intended to gather information on the vehicle’s performance and spot any potential issues. You may look into several potential issues if your OBD II port is giving you problems. Possible issues include a blown a fuse, a broken OBD port, or a loose connection.

Other frequent reasons for an unresponsive connection, issues with the ECU, and human error on your side include OBD port malfunctions (such as not turning the key into the Run position or using a non-compatible diagnostics tool)

You should be able to fix your OBD II port quickly with a little troubleshooting.