While it is a task that can be completed at home, installing the wheel studs might be challenging if you need the necessary equipment. A wheel stud installation tool is useful in this situation. You can save a lot of time and money by having your wheel studs put in properly and without causing any damage to them.

The wheel studs are put into the lug holes of the wheels of your car or truck using a wheel stud installer. A ratchet or impact wrench thread tightens the wheel stud into the installation tool’s and hub’s mounting holes.

What Is a Tool to Install Wheel Studs?

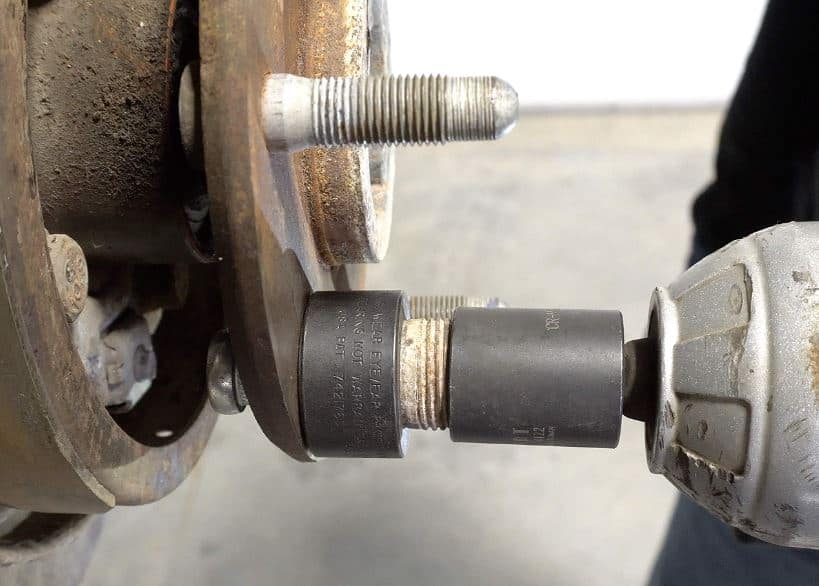

The wheel stud installation tool is a specialized piece of equipment that helps to install wheel studs accurately. Its straightforward construction consists of a thrust bearing and sleeve that pulls a fresh stud into position. It may be used with either an impact or ratchet wrench.

While doing any maintenance on your wheels, such as inserting tire spacers, it is a good idea to inspect the wheel studs and, if necessary, replace them if they are worn out.

Why Use an Installer Tool for Wheel Studs?

Installing wheel studs properly is crucial to ensure your car’s durability and functionality. Many issues, including vibrations, early wear, and even failure, may be brought on by damaged wheel studs. Future costly repairs may result from this.

If you use a wheel stud installation tool, your wheel studs are more likely to be placed accurately and without damage. This method of installing wheel studs is fast and simple, and it might ultimately save you time and money.

How to Make Use of a Wheel Stud Installer Tool

The process of using a wheel stud installation tool is relatively easy.

- First, remove the tire from the wheel hub, and detach the lug nut.

- Remove the hub from the old wheel stud.

- Clean up the hub’s hole next.

- The installation tool’s sleeve should then be inserted into the opening.

- Put the lug nut in the sleeve’s hole.

- Onto the fresh wheel stud, thread the lug nut.

- To tighten the lug nut, use an impact wrench or ratchet.

- This will force the fresh stud into position.

- After removing the installation tool, the lug nut should be manually screwed on.

Advantages of Using a Tool to Install Wheel Studs

The use of a wheel stud installation tool has various advantages. The biggest advantage is that it prevents you from driving—which may be risky—with a broken wheel stud.

Helps to Avoid Cross Threading

Initially, it helps to ensure that your wheel studs are put properly and without damage. The treading is readily harmed during the wheel stud installation procedure. Future issues caused by this include failure, premature wear, and even vibrations.

Cross-threading occurs when the stud’s threads degrade, so they no longer align properly with the lug nut’s threads. If the threads are not correctly aligned before pushing a lug nut on, this may result. It may also occur if you use an impact spanner to remove rusted or overly tightened lug nuts.

When this occurs, removing the lug nut once again becomes exceedingly challenging, if not impossible. Even if you successfully remove it, there is a strong risk that the threads will be severely damaged, necessitating a new stud.

A stud must be changed as quickly as possible if it is cross-threaded. Even one damaged stud might stress the remaining studs to the point of failure when driving. This may lead to a wheel being removed from the automobile while you are driving, which might be quite hazardous. Always err on caution and repair damaged studs immediately since it is better to be safe than sorry.

Simple and Fast Usage

Second, utilizing a tool to insert wheel studs is simple and fast. Avoiding pricey repairs may save you time and money in the long term. It is advisable to do it yourself since mechanics often charge a lot for something like this.

It may be difficult for someone not mechanically inclined to change a wheel stud. Yet it is fairly easy to make and only takes a few minutes. Installing the replacement stud should take, at most, a few minutes if you have all the required tools.

Several kinds of cars can use it.

Third, a range of cars may employ the wheel stud installation equipment. This applies to cars, trucks, SUVs, or even RVs. A gadget that works on all your vehicles is useful if you own multiple vehicles.

Every garage or workshop would benefit from having the wheel stud installation tool. This method of installing wheel studs is fast and simple, and it might ultimately save you time and money. It would help if you considered this instrument whether you are a skilled mechanic or a DIY enthusiast.

Wheel Stud Sizing

It is important to pick the appropriate size of wheel studs. 10mm, 12mm, and 14mm thread sizes are the most popular.

The thread diameter and lug nut size may both be determined with a vernier caliper. The thread pitch and stud diameter are the most crucial measurements since they will decide whether the stud will fit into the hub’s hole.

How Much Does a Wheel Stud Cost?

Depending on the car and your chosen technician, installing a wheel stud will cost you different amounts. A brand-new wheel stud typically costs $10. But, depending on the mechanic, the labor cost might be $50 more each hour.

Can You Drive a Car With 4 of 5 Lug Nuts?

Driving a vehicle with 4 out of 5 lug nuts is not recommended. This is due to the additional strain it puts on the remaining lug nuts, which might result in their loss. Replacing the missing lug nut as soon as possible is recommended since it is always better to be safe than sorry.

Why do wheel studs come loose?

Wheel studs may come loose for a variety of reasons. This includes corrosion, cross-threading, and over-tightening. To prevent these possible issues in the future, it is critical to be aware of them.

How Much Tension Is Needed to Dislodge a Wheel Stud?

Depending on the grade and substance of the stud, different amounts of torque are required to break a wheel stud. However, breaking a wheel stud requires 450 to 500 ft-lbs of power.

What Signs Point to Stretched Wheel Studs?

A symptom that the studs are stretched is when the wheel stud begins to bind when the lug nuts are tightened. Overtightening or removing the lug nuts with an impact gun may also contribute. The studs must be changed if they are stretched.

Conclusion

In conclusion, installing wheel studs is fast and simple with the help of the wheel stud installation tool. It might save you time and money by preventing pricey repairs in the long term. The tool suits various automobiles, including cars, trucks, SUVs, and recreational vehicles. The proper size must be chosen while picking wheel studs.

The thread diameter and lug nut size may both be determined with a vernier caliper. The thread pitch and stud diameter are the most crucial measurements since they will decide whether the stud will fit into the hub’s hole.